| d predetermined |

? |

mm |

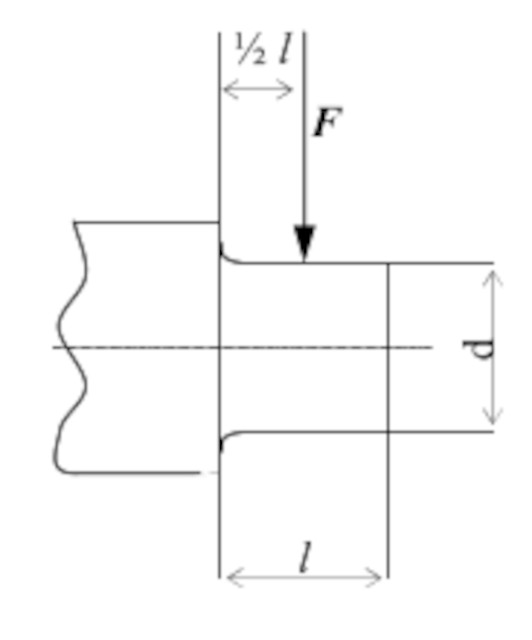

| According length l of the stub = dpredetermined.sqrt((π.σb)/(16.σ0)) |

? |

mm |

| |

|

|

| Diameter dsurface pressure = 4.F/(π.σ0.lpredetermined) |

? |

mm |

| According length l of the stub = dsurface pressure.sqrt((π.σb)/(16.σ0)) |

? |

mm |

| |

|

|

| Diameter d for bending = (16.F.lpredetermined/(π.σb))^(1/3) |

? |

mm |

| According length l of the stub = dbending.sqrt((π.σb)/(16.σ0)) |

? |

mm |

| |

|

|

| Required length l of the stub l for heat dissipation : F.n/w |

? |

mm |

| Is cooling oil required? |

? |

|

| Circumferential speed of the stub = π.dpredetermined.n/60000 |

? |

m/s |

| Friction labour = 0,05.F.v.3,6 |

? |

kJ/h |

| Required cooling oil = friction labour/(specific heat cooling oil.ΔT) |

? |

kg/h |